How Is Leather Made? The Process of Leather Production and Treatment

August 6, 2025

Leather is one of the oldest and most durable materials humans have used in everyday life since ancient times. What once began as a means of protection has, over time, evolved into a symbol of elegance and a standard in the fashion industry. But do you know what happens behind the scenes of your favorite leather products before they appear on store shelves?

Behind every leather bag, jacket, belt, or other clothing item or accessory lies a series of steps that require knowledge, experience, and dedication to quality. In this article, we’ll take you through the complete leather production process – from sourcing raw materials to leather treatment and finally, the finished product in your hands – step by step. It’s time to discover how leather is made in this centuries-old industry.

A Brief History of Leather: From Caves to a Prestigious Symbol

Leather is one of the very first materials humans began to use. As far back as prehistory, when every resource was precious, people realized that animal hides could provide long-term protection. However, raw hides quickly become stiff, brittle, and unusable, so early peoples instinctively began smoking, drying, and greasing them. This was the beginning of what we now know as leather tanning.

Over time, this process developed into a craft tradition and eventually into a full-fledged leather industry. The biggest technological breakthrough came with the invention of chrome tanning in 1858, which allowed for a faster and more efficient tanning process. Today, although there are synthetic materials that imitate natural leather, none can match the value, quality, and unique feel of genuine leather.

How Is Leather Produced Today? Here’s What Modern Leather Processing Looks Like

The use of leather as a material has lasted for more than 7,000 years, and the history and evolution of tanning animal hides is among the oldest human activities. Today, this material is used for everything from clothing and footwear, to furniture and tools, to luxury handbags and sports equipment. But how is leather made in the 21st century?

Below, we break down each step of the modern leather-making process. Each phase prepares the raw hide, chemically stabilizes it, and transforms it into a flexible, durable material suitable for making garments, bags, and other leather products.

The use of leather as a material has lasted for more than 7,000 years, and the history and evolution of tanning animal hides is among the oldest human activities. Today, this material is used for everything from clothing and footwear, to furniture and tools, to luxury handbags and sports equipment. But how is leather made in the 21st century?

Below, we break down each step of the modern leather-making process. Each phase prepares the raw hide, chemically stabilizes it, and transforms it into a flexible, durable material suitable for making garments, bags, and other leather products.

1. Sourcing Raw Materials

It all begins with selecting high-quality raw hides. In industrial terms, this refers to animal hides that, through processing, gain new and improved properties such as durability and softness. Cowhide is most commonly used in production due to its resilience, though other types of animal hides are also used depending on the final product.

As a byproduct of the meat and dairy industry, the leather industry uses materials that would otherwise be discarded. Processing turns them into a long-lasting and useful material that can endure for decades. Manual, as a brand with more than 40 years of tradition, pays special attention to the origin of its raw materials. All leather goods from our workshop are made from natural, eco-friendly, vegetable-tanned cowhide, which guarantees quality.

2. Preserving the Hide

The natural composition of raw hides makes them prone to bacterial growth. To keep animal hides usable until processing, they must be preserved. This is most often done with salting, drying, or a combination of both. The goal of this step is to temporarily protect the hides, preventing decomposition or spoilage before they arrive at a workshop or tannery for further treatment.

3. Leather Processing

This is the point where leather production, as most people imagine it, truly begins. Once preserved hides reach the craftsmen, they undergo a series of mechanical and chemical treatments. First, the hides are soaked in water with special solutions to remove the salt used during preservation as well as any impurities.

Next, the hides are treated chemically and/or mechanically to remove hair, excess fat, and tissue. After these steps, it’s time for the most crucial part of leather production: tanning – the process that transforms hides into durable leather.

4. Tanning

Tanning is the chemical process of bonding proteins in the hide with tanning agents, turning raw animal skin into a stable, long-lasting material. Thanks to tanning, leather gains desirable properties – it becomes resistant to water and heat, and decomposition is prevented.

The so-called “tanning agents” can be mineral, vegetable, synthetic, oily, or combined. There are several tanning methods, depending on the type of agents used:

- Vegetable tanning: The method Manual uses, relying on natural tanning agents such as tannins from tree bark. The result is firm, fully natural leather that ages beautifully with character.

- Chemical tanning (chrome): A faster method that produces soft and flexible leather, most often using chromium salts.

Hides are soaked for several hours in a tannin- or chrome-based solution to ensure full penetration, after which the pH level of the hide is gradually raised (a process called basification) to fix the tannins into the fibers.

At Manual, we primarily use vegetable tanning, because it is not only natural and environmentally friendly but also gives leather an authentic look and long-lasting quality. After this step, the leather is dried, cut, and prepared for final finishing.

5. Finishing and Dyeing Leather

Finishing leather involves a wide range of treatments applied to tanned hides to further enhance both the physical and aesthetic properties of leather products. This step helps eliminate many imperfections that remain after tanning. Mechanical finishing includes processes such as washing, drying, ironing, pressing, stretching, and polishing the leather, while chemical finishing includes dyeing, bleaching, and coating.

After tanning, the first step is dyeing the leather. Dyeing can be done either by hand or with machines, depending on the desired effect. The colors are applied evenly, after which the leather is dried and polished. Next comes finishing – refining the leather’s surface, applying waxes, oils, or coatings (phenols, polymers, acrylics…) that further protect the material and give it its distinctive look and feel.

Finishing leather involves a wide range of treatments applied to tanned hides to further enhance both the physical and aesthetic properties of leather products. This step helps eliminate many imperfections that remain after tanning. Mechanical finishing includes processes such as washing, drying, ironing, pressing, stretching, and polishing the leather, while chemical finishing includes dyeing, bleaching, and coating.

After tanning, the first step is dyeing the leather. Dyeing can be done either by hand or with machines, depending on the desired effect. The colors are applied evenly, after which the leather is dried and polished. Next comes finishing – refining the leather’s surface, applying waxes, oils, or coatings (phenols, polymers, acrylics…) that further protect the material and give it its distinctive look and feel.

6. Design and Crafting Leather Products

Once leather has gone through all the previously described stages of production and treatment, it is ready for use. This is the moment you’ve been waiting for – the design and creation of leather products. The Manual team combines traditional craftsmanship with modern technology and design vision.

Every product is cut, sewn, and assembled by hand. Care is given to every detail, resulting in authentic, long-lasting pieces that impress at first sight and touch. This is the stage in leather production where the difference between mass production and true craftsmanship becomes clear.

7. Quality Control and Packaging

In the Manual workshop, each product undergoes strict quality control. Only after every stitch, edge, and detail has been carefully inspected is the product sent for packaging. Environmental responsibility runs through every part of our business, which is why our packaging is also part of the Manual identity: eco-friendly, elegant, and luxurious, hinting at what awaits inside even before it’s opened.

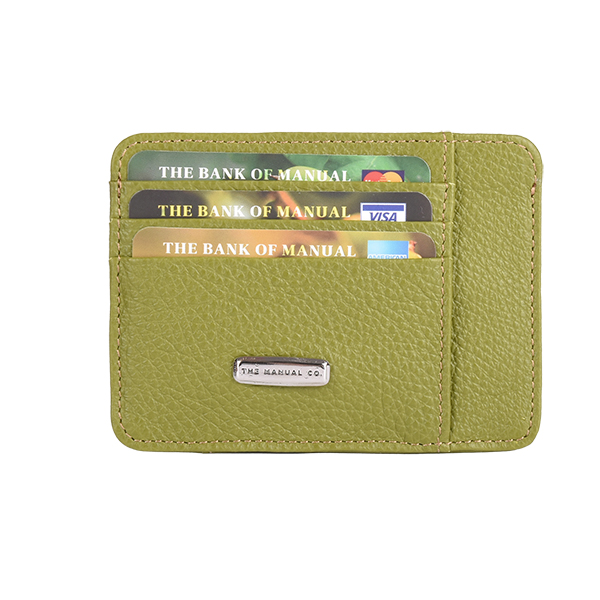

Leather Accessories: Functionality in Elegant Form

Leather accessories form a special category in the world of leather goods. They include all the everyday items that accompany us on the move: leather wallets, bags, belts, cases, travel suitcases… Though seemingly simple, these products require high precision and carefully thought-out design. What makes them unique is the wide range of styles, shapes, and constructions — from soft leather bags that follow the body’s lines to rigid cases for glasses, cards, or laptops.

The production of leather accessories also involves multiple phases: cutting, thinning the edges, reinforcement (with materials such as cardboard or fabric), precise gluing and stitching of parts, adding metal fittings, and finally ironing and polishing. Details such as consistent leather thickness, color fastness, and softness are key quality factors.

At Manual, we do not use synthetic alternatives. Every leather bag, belt, or case in our collection is made from genuine leather, with an emphasis on durability and aesthetics.

TheManual.Co: A 40-Year Tradition of Leather Craftsmanship

So, if you’ve ever wondered how leather is made, now you know that it’s a process requiring time, knowledge, and dedication to detail. From raw animal hide to the finished product, every step has its purpose. Treating and finishing leather is not just an industrial process but a true skill and art form.

For all of you who have been curious about how leather is crafted, or what finishing and processing include, we hope this guide has given you a clear insight into the leather production process. In a world where things are bought quickly and forgotten even faster, Manual’s natural leather products serve as a reminder that tradition, quality, and style never go out of fashion.

When you choose a piece from one of our collections, you’re not just getting a leather accessory that leaves no one indifferent – you’re also receiving a story of decades-long dedication and tradition, woven with care and love into every stitch.

So, if you’ve ever wondered how leather is made, now you know that it’s a process requiring time, knowledge, and dedication to detail. From raw animal hide to the finished product, every step has its purpose. Treating and finishing leather is not just an industrial process but a true skill and art form.

For all of you who have been curious about how leather is crafted, or what finishing and processing include, we hope this guide has given you a clear insight into the leather production process. In a world where things are bought quickly and forgotten even faster, Manual’s natural leather products serve as a reminder that tradition, quality, and style never go out of fashion.

When you choose a piece from one of our collections, you’re not just getting a leather accessory that leaves no one indifferent – you’re also receiving a story of decades-long dedication and tradition, woven with care and love into every stitch.

December 28, 2025

December 28, 2025

The use of leather as a material has lasted for more than 7,000 years, and the history and evolution of tanning animal hides is among the oldest human activities. Today, this material is used for everything from clothing and footwear, to furniture and tools, to luxury handbags and sports equipment. But how is leather made in the 21st century?

Below, we break down each step of the modern leather-making process. Each phase prepares the raw hide, chemically stabilizes it, and transforms it into a flexible, durable material suitable for making garments, bags, and other leather products.

The use of leather as a material has lasted for more than 7,000 years, and the history and evolution of tanning animal hides is among the oldest human activities. Today, this material is used for everything from clothing and footwear, to furniture and tools, to luxury handbags and sports equipment. But how is leather made in the 21st century?

Below, we break down each step of the modern leather-making process. Each phase prepares the raw hide, chemically stabilizes it, and transforms it into a flexible, durable material suitable for making garments, bags, and other leather products.

Finishing leather involves a wide range of treatments applied to tanned hides to further enhance both the physical and aesthetic properties of leather products. This step helps eliminate many imperfections that remain after tanning. Mechanical finishing includes processes such as washing, drying, ironing, pressing, stretching, and polishing the leather, while chemical finishing includes dyeing, bleaching, and coating.

After tanning, the first step is dyeing the leather. Dyeing can be done either by hand or with machines, depending on the desired effect. The colors are applied evenly, after which the leather is dried and polished. Next comes finishing – refining the leather’s surface, applying waxes, oils, or coatings (phenols, polymers, acrylics…) that further protect the material and give it its distinctive look and feel.

Finishing leather involves a wide range of treatments applied to tanned hides to further enhance both the physical and aesthetic properties of leather products. This step helps eliminate many imperfections that remain after tanning. Mechanical finishing includes processes such as washing, drying, ironing, pressing, stretching, and polishing the leather, while chemical finishing includes dyeing, bleaching, and coating.

After tanning, the first step is dyeing the leather. Dyeing can be done either by hand or with machines, depending on the desired effect. The colors are applied evenly, after which the leather is dried and polished. Next comes finishing – refining the leather’s surface, applying waxes, oils, or coatings (phenols, polymers, acrylics…) that further protect the material and give it its distinctive look and feel.

So, if you’ve ever wondered how leather is made, now you know that it’s a process requiring time, knowledge, and dedication to detail. From raw animal hide to the finished product, every step has its purpose. Treating and finishing leather is not just an industrial process but a true skill and art form.

For all of you who have been curious about how leather is crafted, or what finishing and processing include, we hope this guide has given you a clear insight into the leather production process. In a world where things are bought quickly and forgotten even faster, Manual’s natural leather products serve as a reminder that tradition, quality, and style never go out of fashion.

When you choose a piece from one of our collections, you’re not just getting a leather accessory that leaves no one indifferent – you’re also receiving a story of decades-long dedication and tradition, woven with care and love into every stitch.

So, if you’ve ever wondered how leather is made, now you know that it’s a process requiring time, knowledge, and dedication to detail. From raw animal hide to the finished product, every step has its purpose. Treating and finishing leather is not just an industrial process but a true skill and art form.

For all of you who have been curious about how leather is crafted, or what finishing and processing include, we hope this guide has given you a clear insight into the leather production process. In a world where things are bought quickly and forgotten even faster, Manual’s natural leather products serve as a reminder that tradition, quality, and style never go out of fashion.

When you choose a piece from one of our collections, you’re not just getting a leather accessory that leaves no one indifferent – you’re also receiving a story of decades-long dedication and tradition, woven with care and love into every stitch.